How to get the Best Order Proposals

This article describes how to make the most of Shelf Planner and to improve the settings for your products to get the best order proposals.

Are you tired of running out of key products or tying up cash in excess stock?

In this article, we’ll show you how to use Weeks of Stock, Lead Time, and Minimum Stock in Shelf Planner to optimise your purchasing, reduce waste, and keep your shelves stocked with the right products at the right time!

What are Weeks of Stock, Lead Time, and Minimum Stock?

In the program, you can change the settings for your products on different levels. Let's discuss the 3 main parameters you can manipulate to make the most out of your purchasing process.

Weeks of Stock

This measures how long your current inventory will last based on forecasted demand. It’s ideal for fast-moving items or seasonal products where flexibility is key.

Lead Time

This is the time it takes for suppliers to deliver your orders. Factoring in Lead Time ensures you reorder before running out of stock, accounting for supplier delays.

Minimum Stock

Also known as safety stock, Minimum Stock is the lowest level of inventory you aim to keep on hand. It acts as a buffer to cover unexpected demand spikes or supplier delays and is especially useful for stable, predictable items or long lead times.

Why These Metrics Matter

There are 3 main reasons why you want to set the parameters right:

1. Avoid Stock Outs

Combining Weeks of Stock or Minimum Stock with Lead Time ensures you reorder on time to meet demand.

2. Reduce Excess Inventory

Prevent overordering by tailoring stock levels to actual needs, freeing up cash flow for your business.

3. Purchase with Flexibility

Weeks of Stock is great for dynamic, fast-moving products, while Minimum Stock offers stability for slower-moving or critical items.

Set Up Shelf Planner for Your Store

Step 1 - Set Up Weeks of Stock or Minimum Stock

Choose the parameter that fits best for your products:

- Use the Weeks of Stock for items with fluctuating demand or high turnover. Typically, in Shelf Planner, these are your A-grade and B-grade products.

- Use the Minimum Stock for predictable items or for items with long lead times.

Step 2 - Input Lead Time Data

Set Lead Times for Suppliers and, if needed, for specific products. For example, Supplier A may have a 2-week lead time overall, but Product X might take 3 weeks to arrive.

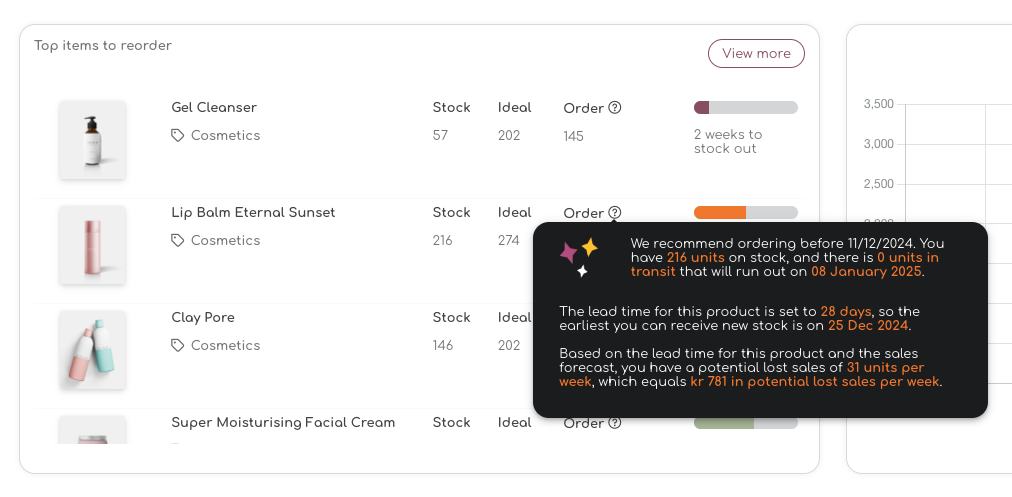

Step 3 - Review Order Proposals

Shelf Planner combines your chosen stock parameters, Lead Time and the sales forecast to recommend precise reorder quantities. If you use Minimum Stock, the system ensures orders are placed when inventory drops to your safety level.

With Weeks of Stock, it calculates based on your coverage period and lead time. We call this the Ideal Stock.

Practical Tips

1. Use Weeks of Stock for High-Demand Products

Fast moving items benefit from flexible, dynamic reordering to match fluctuating sales patterns.

2. Rely on Minimum Stock for Stability

Critical Items or products with predictable demand are best managed with a fixed safety stock to avoid stock outs.

3. Account for Lead Times

Adjust for long or inconsistent supplier lead times by setting higher Minimum Stock or higher Weeks of Stock values.

4. Combine Metrics

Shelf Planner uses both approaches strategically - Weeks of Stock for dynamic products with high variability, and Minimum Stock or Cover for stable items. You will receive recommendations by product on how to best use the parameters, or sit back and let the engine optimise it for you.