Pack Sizes

Pack sizes (also known as lot sizes) play a crucial role in inventory planning, ensuring that orders align with supplier constraints and operational efficiency.

This guide explains how Shelf Planner incorporates pack sizes into Purchase Order Management and provides best practices for leveraging this feature to optimize procurement.

How Pack Sizes Work in Shelf Planner

1. What Are Pack Sizes?

A pack size is the predetermined quantity in which a product is sold, manufactured, or shipped. Suppliers often enforce pack size requirements to streamline production and logistics.

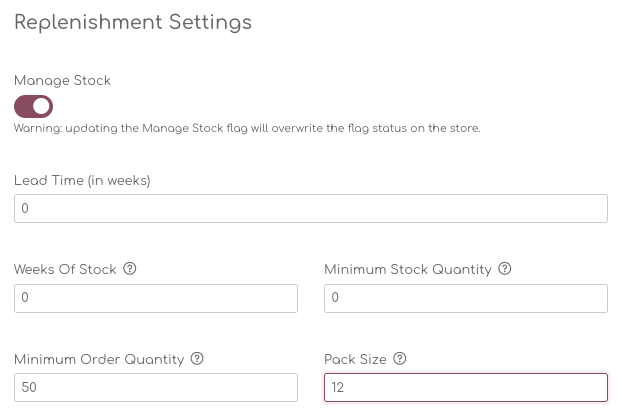

You can set the pack size on a SKU level in the Product Management pages in the Replenishment settings:

Pack sizes affect:

- Order Adjustments: Orders are rounded to the nearest pack size.

- Minimum Order Quantities (MOQs): Orders may need to be increased to meet supplier MOQs.

- Stock Replenishment: Balancing demand forecasting with supplier constraints.

2. How Shelf Planner Uses Pack Sizes in Order Management

When creating a purchase order, Shelf Planner automatically:

- Determines the required quantity based on forecasted demand and stock levels.

- Ensures the order meets supplier MOQs by adjusting the quantity if necessary.

- Rounds up to the nearest pack size to comply with supplier requirements.

- Optimizes across multiple suppliers by comparing pricing, lead times, and pack size constraints.

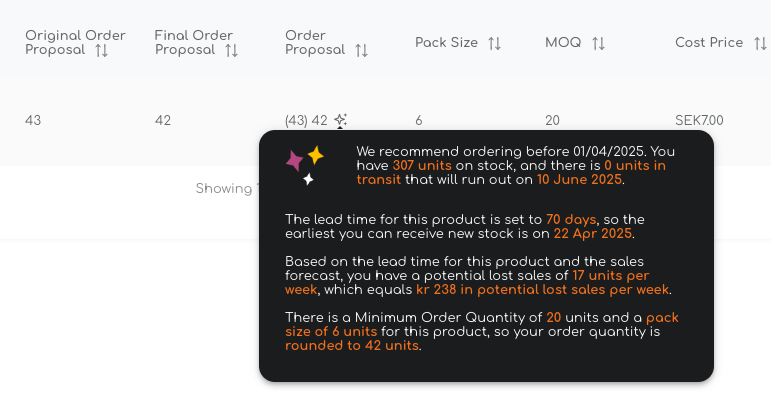

For example, if:

Order Proposal = 7 units

MOQ = 20 units

Pack Size = 5 units

The system will adjust the order to 20 units (MOQ takes priority) and ensure the final quantity is a multiple of 5.

As shown in the example above, the Pack Sizes for this SKU is 6. The original Order Proposal based on Ideal Stock and Demand is 43. The Final Order Proposal taking into account MOQ and Pack Size is rounded to the nearest quantity, in this case 42 units.

Using the Pack Size Feature in Shelf Planner

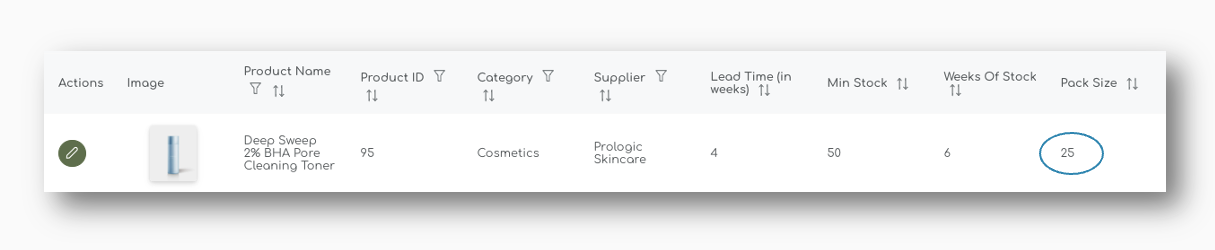

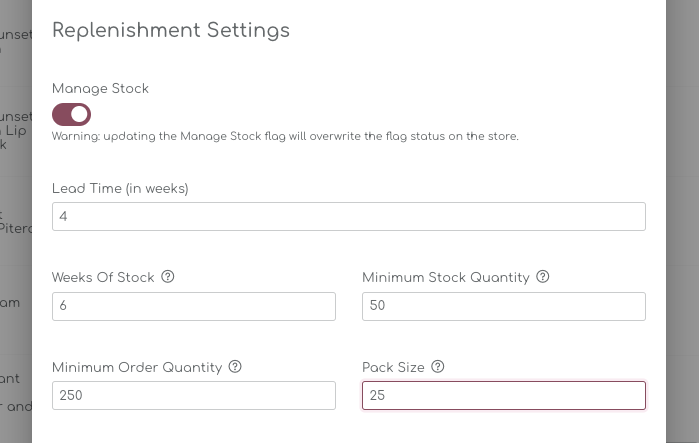

You can change the pack size for each individual product in the Product Settings pages:

In the Product Settings pop up, the Pack Sizes are part of the Replenishment Settings:

1. Adjusting Quantities

Increase or decrease the quantity in increments of the pack size. If needed, add additional products from the same supplier to meet MOQs.

2. Viewing Pack Size Alerts

If an order quantity does not match the required pack size, an alert is displayed. Order Proposals are always rounded to include MOQ's and/or Pack Sizes.

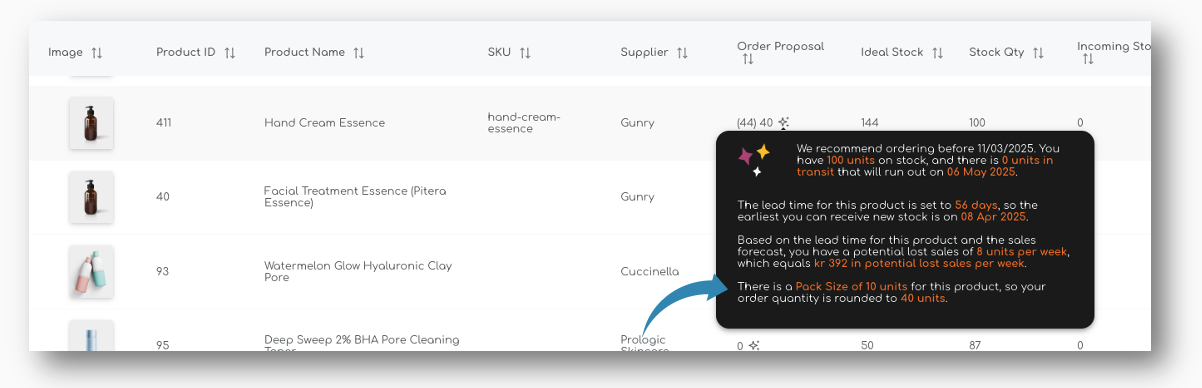

In the example below, there is a pack size of 10 units. The Order Proposal is 44 units, therefor the Order Proposal is rounded down to 40 units:

3. Automating Order Rounding

Shelf Planner automatically rounds order quantities to the nearest pack size to avoid manual adjustments.

The automatic rounding is always considering the nearest pack size, or if an MOQ is present, the minimum order quantity.

What to Consider When Placing Orders

1. Supplier Pack Size Constraints

- Always check supplier pack size requirements before placing an order.

- Some suppliers enforce strict pack sizes, while others allow flexibility.

2. Balancing Pack Sizes with MOQs

- If an MOQ is higher than the order proposal, pack sizes may force additional inventory.

- Optimize by adjusting quantities across multiple products from the same supplier.

3. Inventory Space and Cash Flow Considerations

- Ordering in pack sizes may lead to excess inventory.

- Consider storage capacity and working capital when adjusting orders.

4. Leveraging Shelf Planner's Adjustments

- The system suggests the best order quantity based on pack sizes, MOQs, and demand.

- Review adjustments before finalizing to ensure alignment with business needs.

FAQs

Q1: What happens if I try to order a quantity that is not a multiple of the pack size?

Shelf Planner will automatically round up the quantity to the nearest multiple of the pack size and notify you before finalising the order.

Q2: Can I override the system's pack size adjustments?

Yes, but doing so may result in supplier rejection or increased costs. Always check with your supplier before making overrides.

Q3: How can I minimize excess stock caused by pack sizes?

- Plan purchases based on sales forecasts. Shelf Planner always recommends the ideal order, based on your sales forecast and any incoming stock.

- Adjust order frequencies to align with supplier constraints.

- Use promotions or bundling to move surplus inventory.

Conclusion

Pack sizes are a critical factor in effective inventory management. By leveraging Shelf Planner’s automated pack size adjustments and following best practices, businesses can streamline procurement, reduce excess stock, and improve supplier relationships.