Minimum Order Quantities

Shelf Planner’s Purchase Order Management incorporates a product's Minimum Order Quantities (MOQs) into its algorithms to optimize inventory planning and procurement.

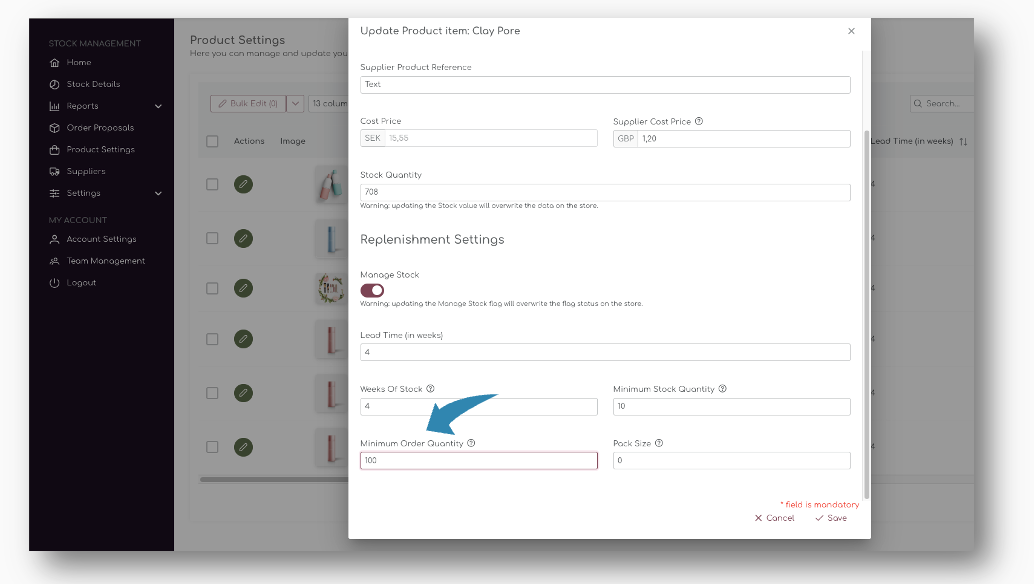

Set MOQ by Product

For each product, you can set a minimum order quantity. You can do this for a single product in the Product Settings:

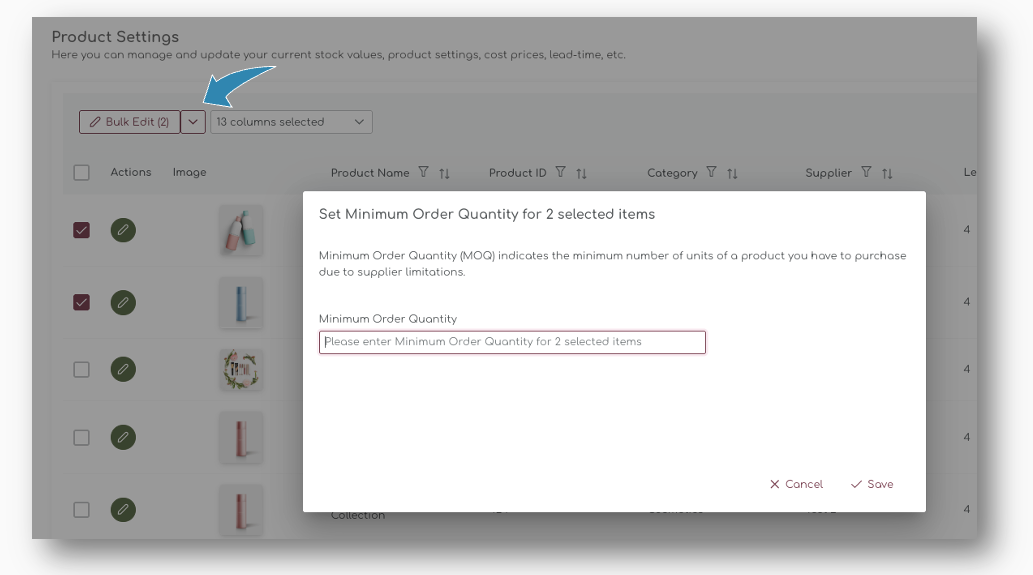

Alternatively, you can use the Bulk Edit on the Product Settings page to enter the MOQ for multiple products at once:

You can also use the mass upload in Excel or CSV files if you want to manage this outside of Shelf Planner and upload it in one go. You can read more about the mass upload on the dedicated page.

Using the MOQ in Shelf Planner

When you use the MOQ for a product, there are a number of other parameters to keep in mind. For each product, Shelf Planner calculates an Ideal Stock, and from there the perfect order proposal. You can also have restrictions due to pack sizes that might round up or down the order proposals.

In the following chapters, we'll try to explain all parameters and scenarios that impact the order recommendations.

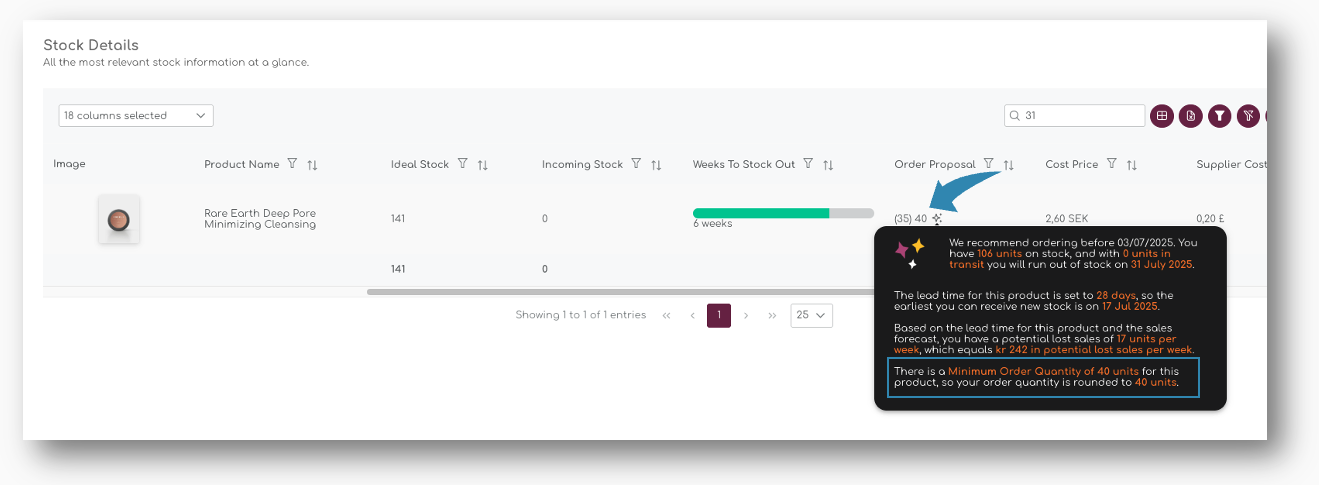

Ideal Stock vs MOQ

The Order Proposal will sometimes need to be rounded based on your MOQ's. We apply a few rules to make sure you don't necessarily order to soon, or too much.

In the example below, the Ideal Stock for this item is 141 units, and there is 106 units on hand. Based on this, and the fact there is no incoming stock for this item, the order proposal is 35 units.

Because there is an MOQ for this product of 40 units, the order proposals is rounded up to 40 units:

This is also explained in the 'smart hover' in the Order Proposal column.

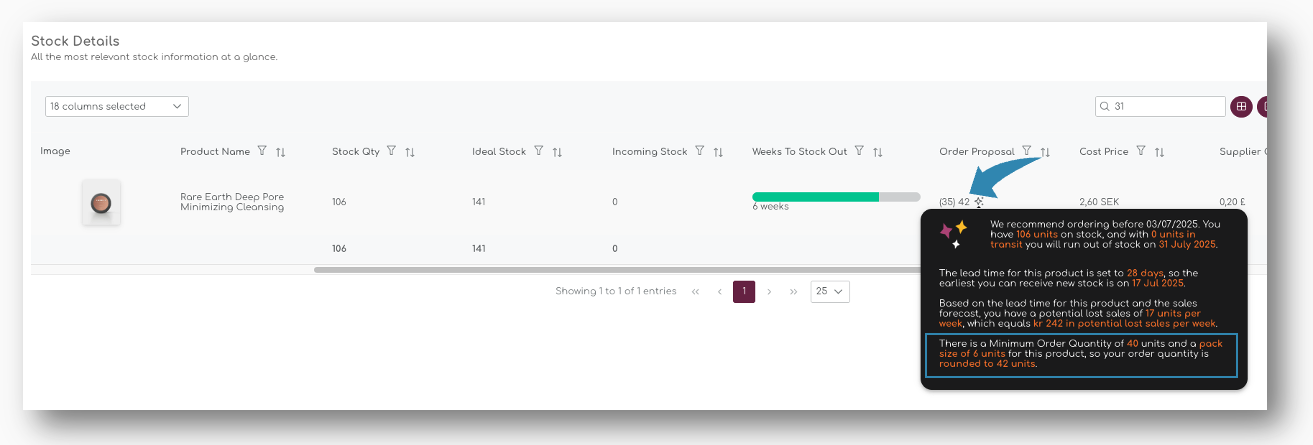

MOQ and Pack Sizes

When you have products that also require ordering in a specific quantity due to pack sizes, the order proposal will also take this into account. For example, if we add a pack size of 6 for this item, the Order Proposal will be rounded to the nearest quantity considering pack sizes, in this case 42 units:

MOQ Total Order Volume (Coming Soon)

Some suppliers require you to order a minimum quantity, or sometimes also a minimum order value.

This is a future feature that is still in development and will be release soon.