October 2025 Release

We’re excited to announce the launch of our new Bill of Materials (BOM) feature in our October Release!

This powerful addition is designed to streamline your inventory and production management, giving you full control over the components, materials, and processes that bring your products to life.

New Feature Release - Bill of Materials (BOM)

What is a Bill of Materials (BOM)?

A Bill of Materials (BOM) is the backbone of your sourcing and production process - a detailed list of all raw materials, components, assemblies, and tools required to manufacture a product. Think of it as a recipe for your products, ensuring you have everything you need, in the right quantities, at the right time.

Why BOM Matters for Your Business

- Accuracy & Efficiency: Eliminate guesswork and manual errors by maintaining a real-time, synchronized view of your inventory and production needs.

- Seamless Integration: Our BOM feature integrates directly with your existing product inventory, ensuring data consistency across sales, planning, sourcing and production.

- Cost & Waste Reduction: Track material costs, set automatic reorder points, and receive automated alerts for low stock, helping you avoid overstocking or shortages.

- Multi-Level Support: Manage complex products with ease using hierarchical BOMs, revision tracking, and customisable templates for both simple and advanced manufacturing workflows.

Key Features of Shelf Planner’s BOM

1. Real-Time Inventory Sync

Every change to your BOM automatically updates your inventory levels, so you always know what’s in stock and what needs replenishing. No more surprises. Smooth.

2. Customizable Templates

Create and manage BOMs tailored to your products, whether you’re producing simple items or complex assemblies. Our intuitive interface makes it easy to add components, adjust quantities, and define production stages.

3. Automated Workflows

Set trigger points to initiate work orders, reorder materials, or notify your team when stock levels reach critical thresholds. Let Shelf Planner handle the repetitive tasks, so you can focus on growing your business.

4. Supplier & Cost Management

Keep supplier information, cost tracking, and alternative component options all in one place. Make informed sourcing decisions and optimize your production costs with up-to-date data.

5. Collaboration & Compliance

Share BOMs with your team, suppliers, and contractors, ensuring everyone is aligned and working from the latest information. Stay compliant with industry standards and reduce the risk of errors or delays.

Who Benefits from BOM?

- Manufacturers: Streamline production planning, reduce waste, and improve collaboration between design, procurement, and manufacturing teams.

- Retailers & Wholesalers: Gain visibility into your product components, manage variations effortlessly, and ensure you’re always stocked for demand.

- E-commerce Businesses: Integrate BOM with your, WooCommerce, or PrestaShop (coming November) store to sync inventory and production data seamlessly.

How to Get Started

- Navigate to the BOM pages: Access the new BOM feature from your Shelf Planner dashboard.

- Create Your First BOM: Start by creating material, listing the components for one of your products. Include ready made products (Finished Goods) or build a custom BOM from scratch.

- Manage Material Inventory: Shelf Planner automatically updates stock for components and material with real-time updates and automated alerts.

- Set Up Workflows: Define your production stages, reorder points, and supplier details to automate your processes.

Miscellanious Updates & Improvements

Also in this release:

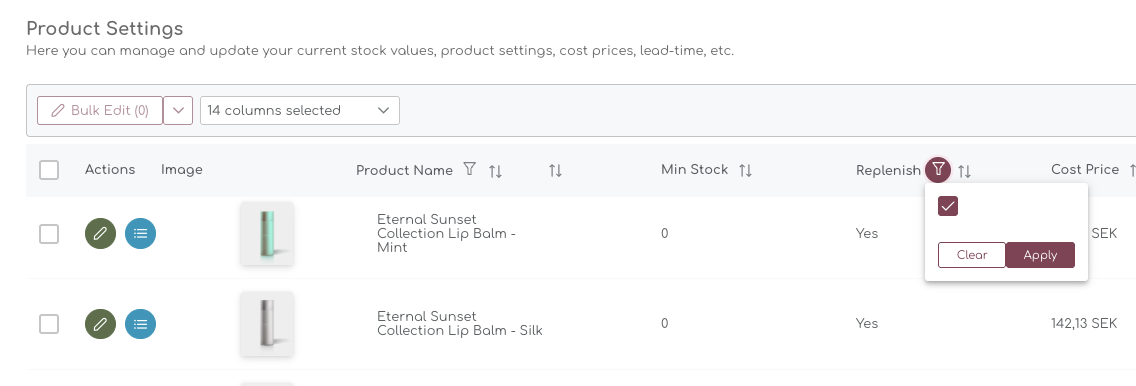

Replenishment Flag

Not all items need replenishment and we have had many request to add a measure that allows for easier filtering across all tables. You can now set a 'Replenishment Flag' for each item which will allow you to exclude them from the tables, but also from all calculations.

You can filter on any report to either include or exclude items:

Miscellaneous Bug Fixes & Security Improvement

- Fixes an issue with sorting of columns on the Order Proposal pages, where quantities were not filtered correctly.

Thanks again for all the positive and constructive feedback!