To Restock (Material)

Restock Material - Order Proposals

Shelf Planner generates Order Proposals for all your Materials, based on your customer demand, actual sales and external factors.

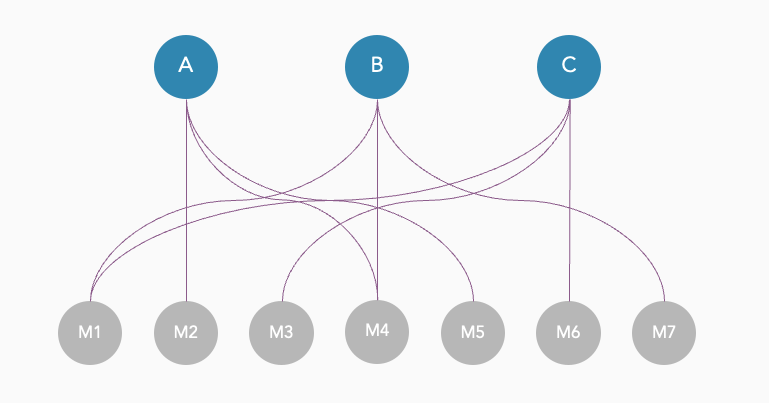

When you create a Bill of Material, or when you link material to products, we automatically calculate the consumption of material across all products.

As illustrated in the example above, a Material (M1, M2, ..) can be linked to a number of products (A, B, C). Based on the forecast for each product, we calculate the consumption of each material.

Step 1: Review Order Proposals for Material

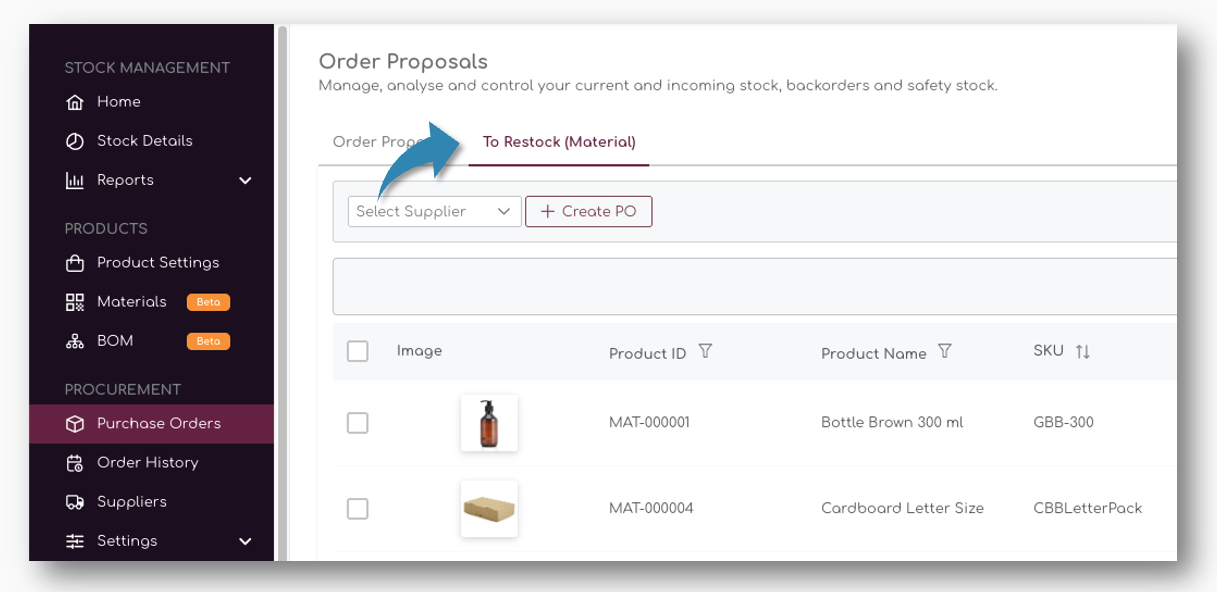

For the restocking of material, a dedicated tab is created on the Purchase Order page:

The main table on the "To Restock" page shows all products that can be reordered and have a Order Proposal generated.

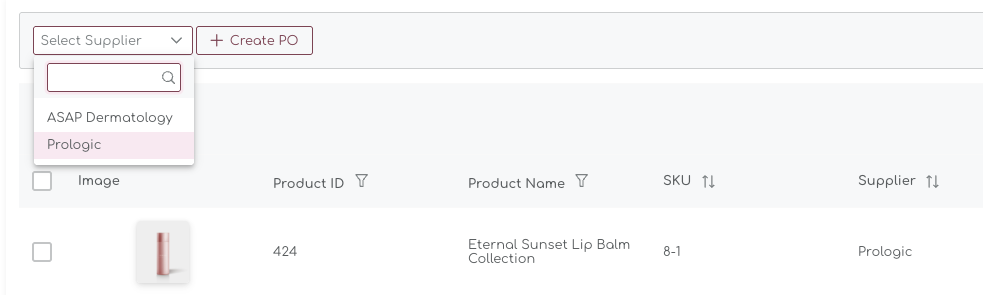

You can filter the table by selecting a supplier in the filter selection on top of the table, or use any of the filters in the columns:

The table is automatically filtered on items that need to be replenished. If you want to see all items, also items without order proposals, you will have to change the settings under the Replenishment Settings.

Order Recommendations for Material

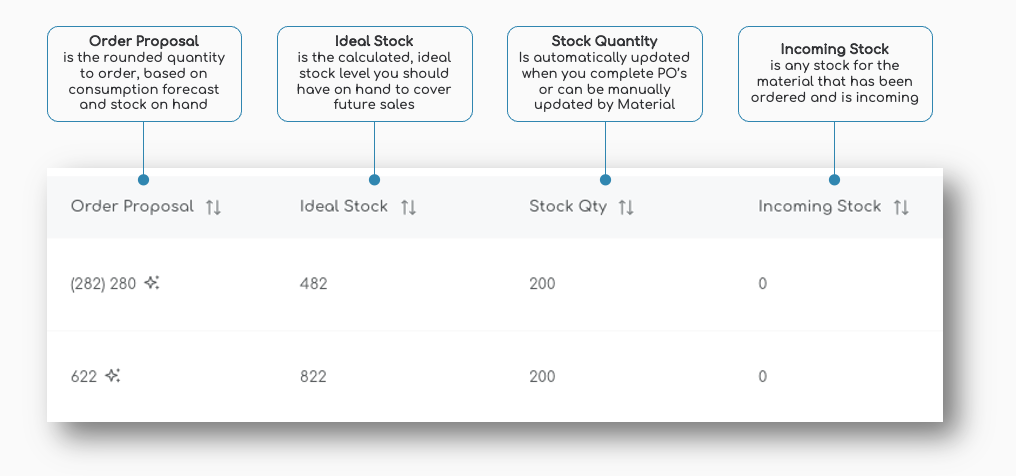

When you navigate to the Order Recommendations section, you'll see a table with the following columns:

| Column | Description |

|---|---|

| Product Name | Name of the Material |

| Supplier | Supplier Providing the Material |

| Order Proposal | Recommended quantity to order, based on consumption forecast for this material. |

| Ideal Stock | Optimal stock level for the material, calculated as Weeks of Stock (WoS) × Weekly Consumption. |

| Stock Quantity | Stock Quantity of the material. This is automatically updated based on the sales of products the material is linked to. |

| Incoming Stock | Quantity of the material already on order and expected to arrive. |

| Weeks to Stock Out | Estimated number of weeks until the material runs out, based on current stock and consumption. |

| Forecast N4W | The Forecast for the Next 4 Weeks (N4W), shows the projected consumption of the material, based on the sales forecast of the products it is linked to. |

| Forecast N8W | The Forecast for the Next 8 Weeks (N8W), shows the projected consumption of the material, based on the sales forecast of the products it is linked to. |

The system automatically calculates the Ideal Stock for a material, based on the current stock on hand, any incoming stock, and the consumption forecast for the coming weeks. This is best illustrated below:

Order Proposal Calculations

The sales forecast that is generated for all your products, in combination with a number of parameters is used to determine your final order proposals.

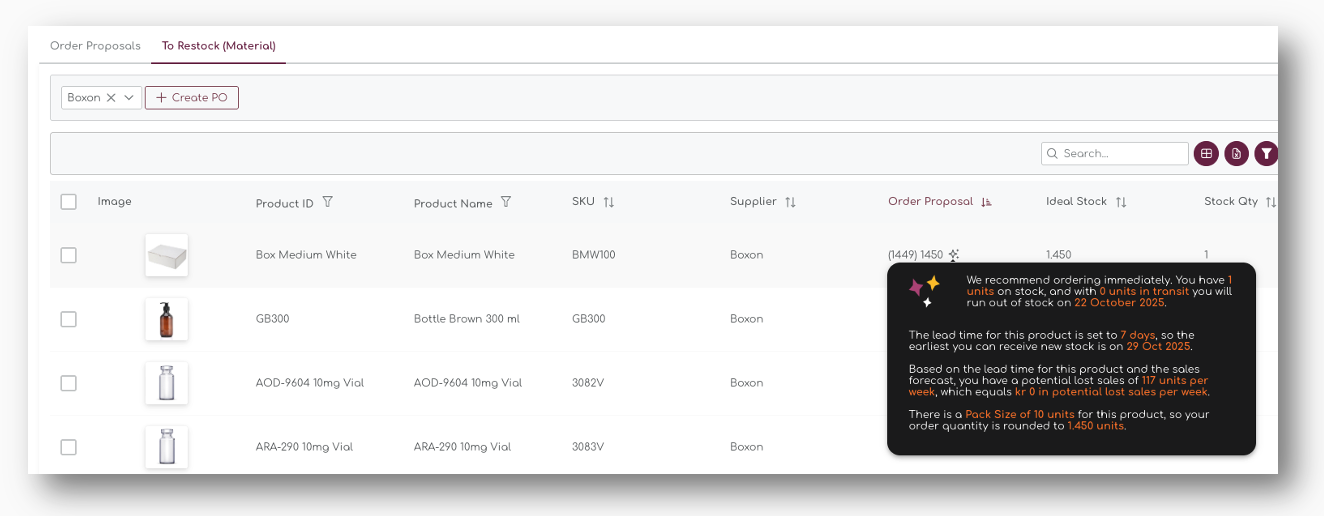

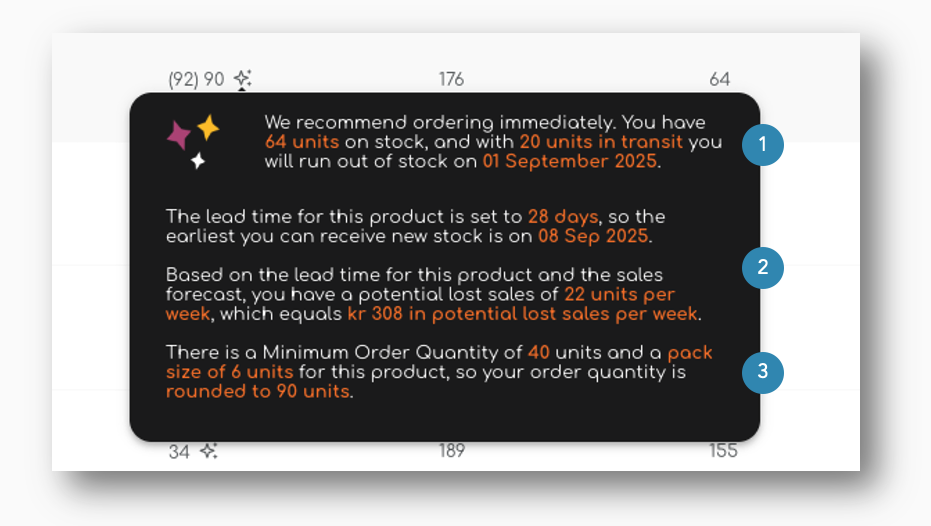

For each item, we always show the reasoning behind the quantity, as you can see in the example below:

We will walk through the recommendation logic using this example.

1. When To Order

As you can see in the example above, the system recommends to 'order immediately'. It knows you currently have 64 units in stock and 20 units incoming, and based on the sales forecast this item will run out of stock the 1st of September.

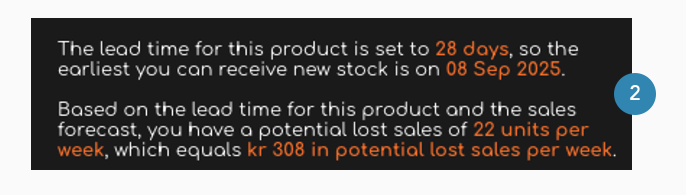

2. What Happens if you don't reorder

The second piece of information is the Lead Time that is set for this product, in this case 4 weeks, or 28 days. This means you will not be able to receive new stock until the 8th of September. This is why the system suggest to order immediately.

Based on this information, plus the fact that you will run out before you can have new stock on hand, the system will also show you how much 'Lost Sales' you might have, in this case 22 units per week, which equals 308 SEK.

3. Final Order Proposal

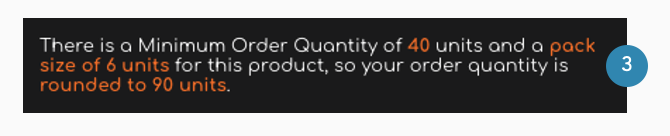

In the final order proposals, the system also looks at any Minimum Order Quantities or Pack Sizes you might have for this product. In this example, there is an MOQ of 40 units and the item is sold by the vendor in pack sizes of 6 units, therefor the Order Proposal is rounded to 90 units. (15 x 6 packs)

As shown in the example above, there are a lot of rules and logics in place to come to a final order proposals, but everything starts with the so called Ideal Stock for the item. in the following chapters, we will explain all the parameters and how they work together.

Ideal Stock

Shelf Planner uses a so called 'Ideal Stock' to calculate the best order proposal for each SKU. The Ideal Stock is calculated by the Shelf Planner engine and is based on:

- Sales Forecast for all items that use this material

- Incoming stock for the material, based on Purchase Orders placed

- Current stock

- Weeks of Stock*

- Lead Time

* For Materials, we don't use a Weeks of Stock parameter, instead we use the Weeks of Stock parameter that is used by the Products that consume this material. For example, when 2 products consume this material, we use the highest Weeks of Stock parameter of the two products.

Every night, your sales forecast for all products in your store is updated. This ensures you always have the latest picture of each product's performance and trends. Based on the Weeks of Stock (the amount of weeks of sales you want to keep in stock) and the lead time from your different suppliers, we can calculate the best re-order point for all materials.

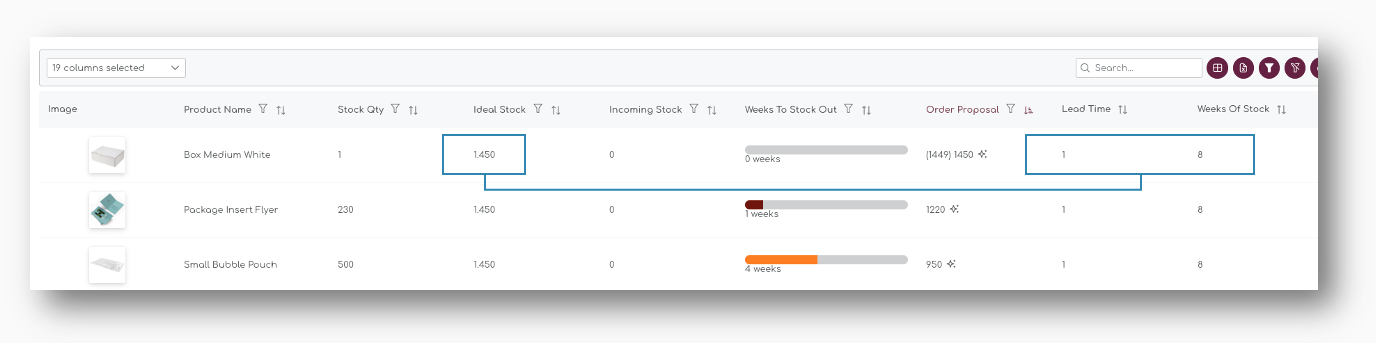

In this example, the Ideal Stock for the Box Medium White is 1.450 units, based on a Weeks of Stock of 8 weeks, and a Lead Time of 1 weeks. This means that the Ideal Stock of 1.450 units is based on the next 9 weeks of sales:

Current Stock

The Current Stock is the Stock you have in your warehouse for the material.

In the example above, the current stock is 1 unit and there is no incoming stock for this material.

Incoming Stock

The Incoming or Inbound Stock refers to the stock that is incoming or in transit. When you place purchase orders, we will track the expected delivery date for all items.

When a Purchase Order for Material has been completed, the stock in your warehouse will be automatically updated.

Order Proposal based on Ideal Stock

The Shelf Planner engine uses your sales forecast for the coming weeks to understand whether you are understocked, or overstocked.

You do not necessarily want to replenish all the items in your store. You can select a single item or place multiple orders for the same item over time.

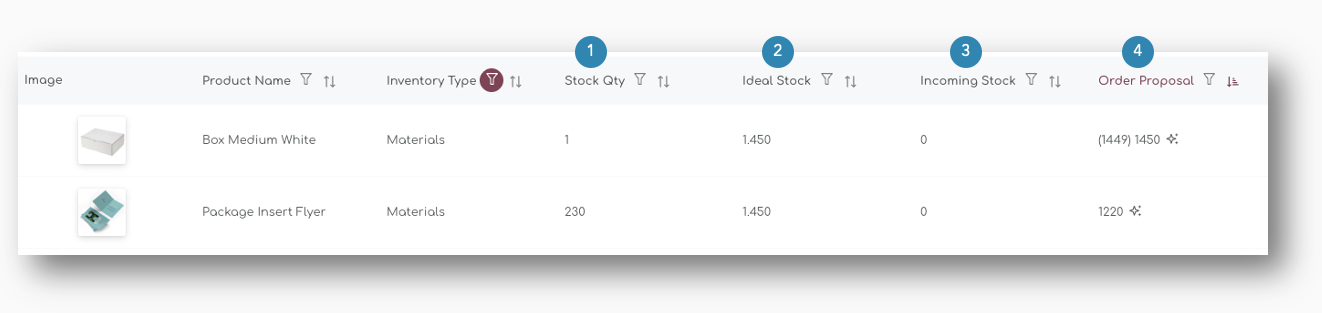

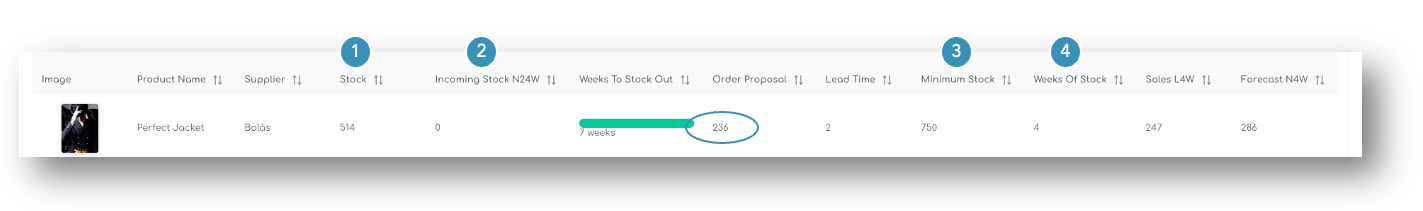

In the example below, the Order Proposal for the selected product is 1450 units (4). This number is based on:

- Ideal Stock (1) for the material (based on all product's sales forecast this material is linked to)

- Current Stock (2) - your current inventory of the material

- Inbound Stock (3) - any incoming orders that you placed

For more information on how we calculate the Ideal Stock, please have a look at the article Ideal Stock.

Order Proposal based on Safety Stock

For all Materials, you can also set a Safety Stock. Especially for material you use for a wide variety of products, such as packaging and shipping material, you can set a safety stock.

Our machine learning algorithms will pick up this behaviour and highlight these items in that case. For some of these products, it might be better to set a Safety Stock threshold instead of using the Ideal Stock for the Order Recommendations.

While the Ideal Stock is used to make sure you set up your business as lean as possible, you don't want to get into a situation where you cannot sell

Set Safety Stock

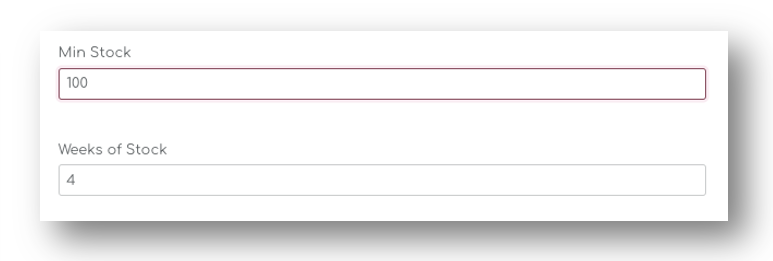

On the Material pages, you can set a minimum stock for each material:

In this example, we set the Minimum Stock to 50 units. Instead of using the Weeks of Stock and the Lead Time to define the order proposals, the Min Stock is used to determine the Order Proposal:

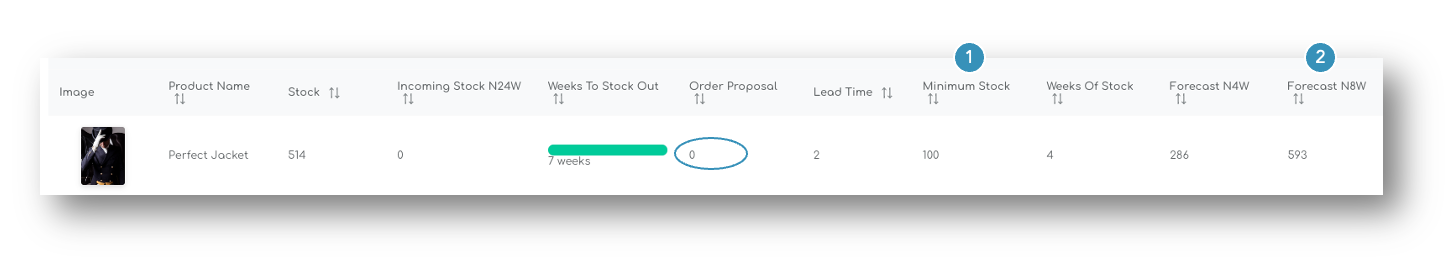

As shown in the example above, the current stock (1) is 514 units. There is no incoming Stock (2). Becuase the minimum is set to 750 units, the Order Proposal is 750 - 514 = 236 units.

The Weeks of Stock (4) is in this example ignored.

When we set the Minimum Stock back to 100, the Order Proposal is recalculated:

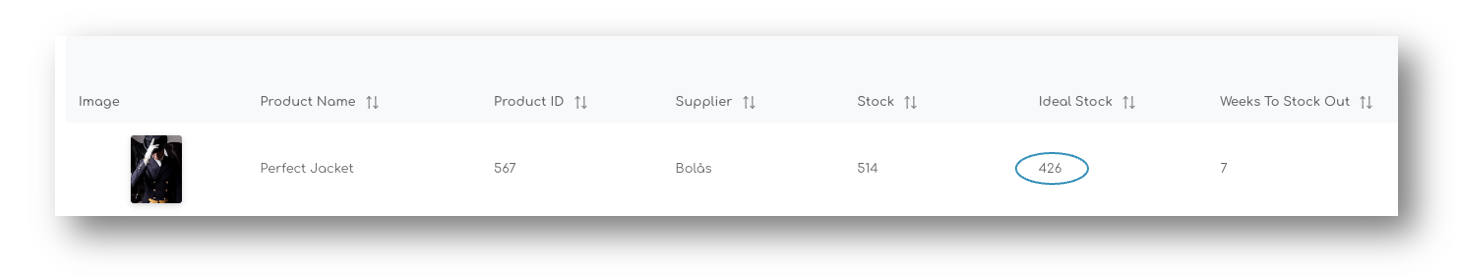

The Safety Stock is now set to 100 and the Ideal Stock is using the Weeks of Stock and Lead Time (1). With a Lead Time of 2 and a Weeks of Stock setting of 6 weeks, the Ideal Stock uses 6 weeks of Sales to calculate the Ideal Stock, in this case 426 units:

As you can see in the example below, the Forecast for the next 8 weeks is 593 units, hence the Weeks to Stock out is 7 weeks and technically, this item is 'overstocked':